When it comes to industrial applications requiring reliable and efficient flow control, Durco plug valves stand out as a top choice. These valves are known for their robust construction, long service life, and versatility in a wide range of operating conditions. To truly unlock the power of Durco plug valves, it is essential to understand their design, operation, maintenance, and troubleshooting procedures. In this comprehensive guide, we will delve into the key aspects of Durco plug valves and provide insights on how to maximize their performance.

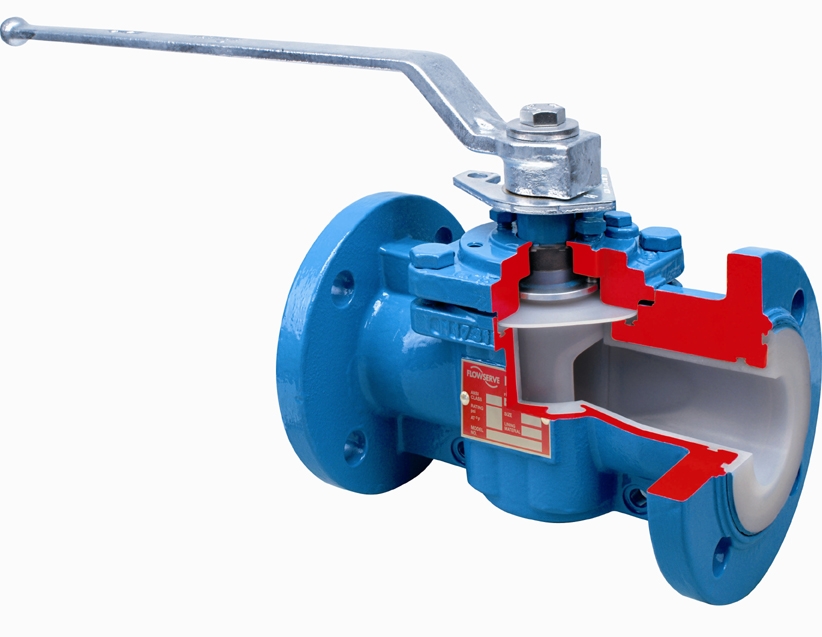

First and foremost, let's explore the design of Durco plug valves. These valves feature a tapered or cylindrical plug that can be rotated within the valve body to control the flow of fluids. The plug is designed to create a tight seal against the valve seat, preventing leakage and ensuring precise flow control. Durco plug valves are available in various configurations, including lubricated and non-lubricated designs, as well as different materials of construction to suit specific application requirements.

When it comes to operation, Durco plug valves offer a simple and reliable flow control solution. By rotating the plug within the valve body, users can easily adjust the flow rate of the fluid passing through the valve. The tight seal created by the plug and seat ensures leak-free operation, even in high-pressure or high-temperature environments. Durco plug valves are widely used in industries such as oil and gas, chemical processing, petrochemical, and power generation, where reliable flow control is critical.

Proper maintenance is essential to ensure the long-term performance of Durco plug valves. Regular inspection, lubrication, and replacement of worn parts are key to preventing issues such as leakage or valve failure. It is important to follow the manufacturer's recommended maintenance schedule and procedures to keep Durco plug valves operating at peak efficiency. Additionally, proper storage and handling practices can help extend the service life of these valves and prevent premature wear or damage.

In the event of a malfunction or performance issue, troubleshooting Durco plug valves requires a systematic approach. Common problems such as leakage, sticking, or poor flow control can often be traced back to issues with the plug, seat, or actuator. By carefully inspecting these components and identifying any signs of wear or damage, users can pinpoint the root cause of the problem and take appropriate corrective action. In some cases, simple adjustments or replacements may be all that is needed to restore the valve to optimal performance.

One of the key advantages of Durco plug valves is their versatility in a wide range of applications and operating conditions. Whether handling corrosive chemicals, abrasive slurries, or high-temperature steam, these valves are designed to provide reliable and efficient flow control. With the ability to withstand high pressures and temperatures, as well as harsh chemicals and abrasive particles, Durco plug valves offer a robust solution for demanding industrial environments.

In conclusion, Durco plug valves are a reliable and efficient flow control solution for a wide range of industrial applications. By understanding the design, operation, maintenance, and troubleshooting procedures of these valves, users can unlock their full potential and maximize their performance. With proper care and attention to detail, Durco plug valves can provide years of trouble-free operation and help optimize the efficiency of industrial processes. Whether used in oil and gas, chemical processing, or power generation, Durco plug valves are a trusted choice for reliable flow control.